Within this activity, Neksigol Mushovir tests the bioreactor technology for biogas production, which is easy to operate and affordable in terms of cost, sets up demo plots, conducts experiments, adapts it to the local country context, and offers the system to livestock farms.

Sistema.bio has developed a technology to make highly efficient and sustainable modern biogas systems. It has already installed more than 60,000 units in India in different climatic and geographical conditions. To benefit the dairy farmers of Central Asia (started from Tajikistan), it is partnering with Neksigol Mushovir to spread the benefit of biogas to Central Asia. The initial pilot will help both parties understand the feasibility of this project at scale. Eventually, the effort will be made to leverage financial innovations like carbon credits to enable this product to reach the majority of dairy farmers.

| Use case | Sustainable farming | Supply chain management | Access to market | Agricultural Extension and Advisory Services |

| Funding | Funded by the U.S. Agency for International Development (USAID) and implemented by ACDI/VOCA |

| Focus Area | The goal of the project is to achieve a reduction in methane and nitrous oxide (from synthetic fertilizer use) emissions through the development of a thriving market for biodigesters technology in the Tajikistan market. NM will collaborate with Sistema.bio, a global pioneer in biodigester technology on delivering the system to Tajikistan and transferring technical skills. In the next phase NM will start promotion of the biodigester technology in three regions of Tajikistan; Khatlon, Sughd, and DRS with a focus on creating a robust and scalable business model for the biodigester market, capitalizing on the strengths of each stakeholder through the following specific objectives: (1) Co-create an innovative approach for biogas/biofertilizer production from manure adapted to the country context (2) Launch pilots for driving product-market fit (3) Scale interventions for capturing an entire market |

| Duration | January 2 — December 31, 2024 |

| Coverage | The target areas are Sughd, Khatlon, and DRS, and the target districts are determined in the process of selecting entrepreneurs and farmers for cooperation. |

| Beneficiaries | Small and medium-sized farmers, small and medium-sized dairy processing enterprises, young women and men from rural area |

| Partners | Sistema.bio, Ministry of Agriculture, State unit enterprise «Center for Digitization and Professional Development of Agricultural Specialists» of MoA |

| Key activities | Below is a list of main expected results of the project: — 8 biodigester packages of 4 different sizes imported to Tajikistan and ready for demonstration — At least 30% investment made by NM for co-creating, piloting & scaling of anaerobic digestion technology in TJK — At least 5 technical experts of NM trained as national technical experts and trainers in anaerobic digestion technology — Biodigester technology adapted to the Tajikistan context and needed adaptation measures documented — Results of experiments with installing greenhouses to cover biodigester installations and to reach the necessary temperature during cold months and mixing cow and poultry manures to increase biogas production potential documented and applied — 8 biodigester packages of 4 different sizes piloted in three agricultural regions (Khatlon, Sughd, and DRS) in cooperation with local farmers and small agribusinesses — At least 30% investment made by local farmers & small agribusinesses for launching pilots through in-kind & cash contributions — Feedback from pilot customers collected and applied to configure different sets of functionalities for creating a market-winning product — Piloted biodigester installations documented to generate data for the economic, environmental, & social impact calculation — At least 140 tons of waste treated by the pilot customers — At least 5 200 m3 of biogas produced by the pilot customers — At least 430 tons of biofertilizer produced by the pilot customers — At least 150 tons of CO2e mitigated in the cattle farms of pilot customers — Communication materials (case studies, white papers, blog posts, and TV/radio programs) created and disseminated with the active input from initial customers, highlighting the benefits of biogas/biofertilizer production, operation/handling of the biodigester, and purchase options — At least 3 Open Field Days organized at each farm out of 8 with installed biodigester system with participation of at least 500 interested stakeholders — At least 40 rural youth from all over the country trained as local specialists in anaerobic digestion technology to upgrade to higher-value activities — At least 40 new job opportunities created for rural youth for executing orders on biodigester installation — At least 190 tons of biofertilizers sold to farmers by pilot customers — With at least 15 new customers signed contracts for biodigester installation |

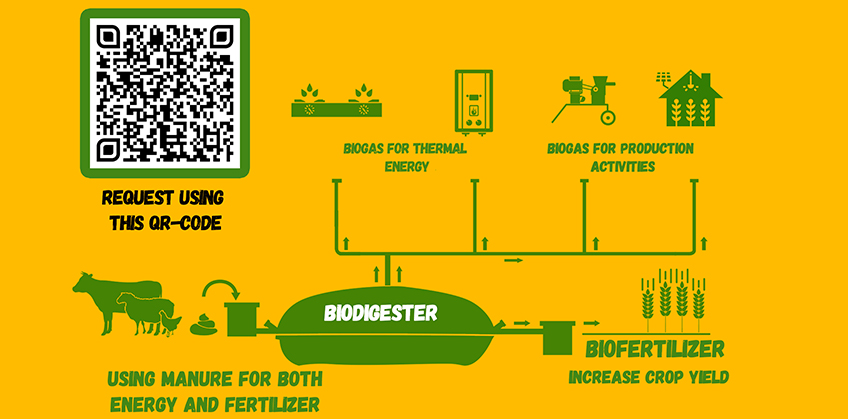

| About transferred technology | Within this activity, a high quality Hybrid Reactor digester technology is proposed for processing livestock and poultry manure. The digester processes manure mixed with water to produce biogas and biofertilizer. Biogas can be used to cook meals or heat water. It can also be used for pen heaters and greenhouses, and even for milking machines, water pumps, chaff cutters, etc. Biofertilizer improves soil fertility and increases crop yields. The biodigester works with manure from different animals such as cows, sheep, goats, horses, rabbits, chickens, etc. However, cow and chicken manure have a better performance in biogas production. |